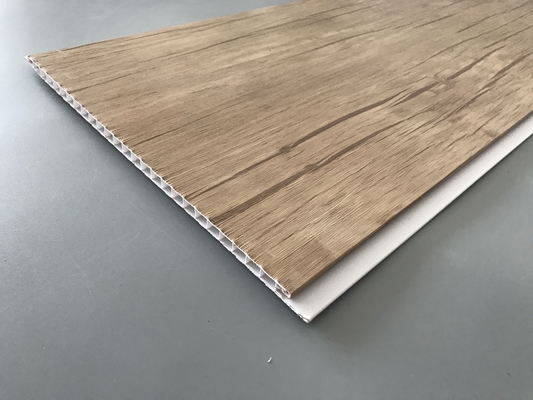

Wood Color PVC Fireproof Plastic Laminate Panels Specification 250 × 7.5mm

PVC Plastic Laminate Panels are constructed through PVC extrusion under a controlled environment. This is a hot PVC extrusion process.

• Due to the PVC composition, and the construction of the panels with additional strengthening cross members, PVC Plastic Laminate Panels are rigid and strong; however they are lighter, less thick therefore space saving, and easier to handle than traditional PVC Plastic Laminate Panels or wood core equivalent panels.

• PVC Plastic Laminate Panels offer additional benefits such as being considerably easier to install, hygienic, fully waterproof material construction, and class B1 fire rating for commercial and domestic use.

• PVC Plastic Laminate Panels are for internal use only.

PVC Plastic Laminate Panel Description:

|

Name

|

Wood Color PVC Fireproof Plastic Laminate Panels Specification 250 × 7.5mm |

|

Size

|

Width 250mm; Thickness 7.5mm |

|

Weight

|

2.6kg/sqm; 3kg/sqm |

|

Packing

|

put 10 pieces into one bag, and normally the length is 5.8m or 5.95m |

PVC Plastic Laminate Panel Benefits:

|

A.

|

Light weight, fireproof and waterproof, anti-corrosion:

PVC ceiling is not only light weight, waterproof and moistureproof, but also has the characteristics of acid fast and alkaline. It is an ideal material for installation in the kitchen and bathroom ceiling. Usually PVC ceiling panel is also the main selection of kitchen and toilet ceiling.

|

|

B.

|

Lower cost compared with other ceiling material

PVC panel is an economic decoration material, the price is cheaper compared with other such as Aluminous panel and wood panel, it is one of the most popular decoration materials.

|

|

C.

|

Environmental protection:

A lot of people are worried about the smell of PVC panel, in the fact if you choose regular factory of the PVC panel, it is non-toxic and tasteless, no stimulation to the skin and respiratory system, for those of timber and paint allergic people, PVC panel is very suitable to use in the home or public place.

|

| D. |

Convenient installation and disassembly

PVC panel is easy to install, and if damaged, it is very convenient to replace. As long as the end of the strip is removed, the panel will be taken out, replace the damaged panel with a new one, and then reinstall the strip.

It is easy to install and disassemble the pvc panel, when the pvc panel is broken, only need to remove the profile of the end, then take the broken panel and replace a new one.

|

| E. |

Easy to clean

Usually we choose a material for our kitchen and bathroom, we should consider the cleaning problem. Because the kitchen is often exposed to oil fumes, and more vulnerable to some pollution. But if you choose the pvc panel for decoration, you don’t need to worry about the problem of cleaning, because PVC panel is a very clean material.

|

| F. |

Various color designs for choice

The surface of pvc ceiling could be glossy printing and hot stamping, there are lots of different color design, such as marble, wooden and cartoon. we also can produce the colors according to clients' requested. so the finish assembly of pvc ceiling system could offer suitable and beautiful decorative.

|

PVC Plastic Laminate Panel Loading Quantity:

| SPECIFICATION |

QUANTITY (package) |

| width |

thickness |

20GP |

40HQ |

|

25cm

|

7mm |

255 |

610 |

| 7.5mm |

240 |

565 |

| 8.0mm |

225 |

530 |

| 9.0mm |

200 |

470 |

|

20cm

|

6.0mm |

366 |

870 |

| 7.0mm |

315 |

745 |

| 7.5mm |

292 |

700 |

| 8mm |

275 |

650 |

| 8.5mm |

260 |

615 |

| 30cm |

6.0mm |

251 |

595 |

| 7.0mm |

215 |

510 |

| 7.5mm |

201 |

476 |

| 40cm |

6mm |

240 |

280 |

| 9mm |

160 |

280 |

| 60cm |

7mm |

550 |

1280 |

How To Install PVC Plastic Laminate Panel?

1) For a perfect finish we recommended using our finishing trims. Trims are used at the start and end of panel runs, and on any corners. We recommend that 2-part finishing trims are used, in which case the back part of all trims should be fixed first.

2) Working from left to right, measure and cut the first panel to the correct length. Boards can be cut with a tenon saw, a jigsaw or a fine toothed hand saw.

3) Fix in position using a plumb line or spirit level to ensure that this first length is perfectly vertical. If you are using nails, screws or staples, fix through the lip at the back edge of the board so that the fixings are hidden when the next board is pushed into place.

4) If fixing in a shower cubicle apply bathroom grade silicone (apply a bead of sealant vertically along the back leg of the panel that you have fixed).

5) Push the next panel into position and fix as before.

6) Once all panels have been fixed, fit the front section of the two-part trims to finish the installation.

Company Advantages:

HAINING OASIS BUILDING MATERIAL CO.,LTD is an professional manufacturer and exporter of pvc panel.

We have nine advanced producing line for pvc panel. Our factory always focus on quality control, scientific management and R&D, so that we can supply the high quality, competitive price and best service for our clients. That is why our products enjoy good markets in worldwide, such as Latin America, Middle east, Africa and south asisa.

On 2015, we established first branch company at Bogota,Colombia, loacated at Calle 68 #22-43.

On 2016, we set another warehouse in Colombia, the address is Carrera 22#14-60,Bogota.

On 2017, we plan to set more warehouse in another city of Colombia, Such as Cali,Baranquilla.

With “quality first, best credit, clients supreme”, welcome warmly you to inquiry and visit us

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!