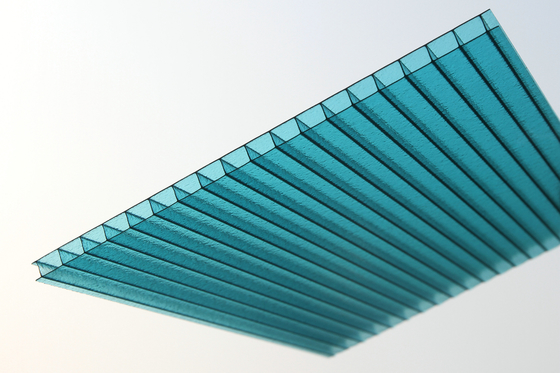

Anti UV Polycarbonate Insulated Roofing Sheets / Twin Wall Polycarbonate Panels

Application of Polycarbonate Insulated Roofing Sheets

1) Roofing for greenhouse, swimming pool, shopping malls, commercial streets.

2) Sunshade for stadiums and bus stops, gazebo, open air carport.

3) Lighting canopy for corridors, passages and subway entries.

4) ATM machine covers, telephone booth, gateways, garages.

5) Sound and heat insulation wall for expressways and houses.

6) Instead of glass, decoration door, curtain wall.

7) Soundproof material for partitions.

8) Unbreakable material for glazing widows, roof glazing.

9) Lighting of modern villa, rain-proof lighting shed of underground garage entryway.

10) Front wind shields of motorcycles, airplanes, trains, liners, vehicles, motorboats, submarines and riot shields.

Polycarbonate Insulated Roofing Sheets Specification

1. Width: 2.1 meters

2. Length: 11.8 meters

3. Thickness: 6mm

4. Min. Bend Radius: 1050mm

5. K value: 3.6W/㎡K

Polycarbonate Insulated Roofing Sheets Technical Date

|

Characteristics

|

Unit |

Date |

|

Light transmission

|

% |

91 |

|

Impact strength

|

j/m |

850 |

|

Density

|

g/cm2 |

1.2 |

|

Flexural strength

|

N/mm |

2100 |

|

Modulus of elasticity

|

Mpa |

2400 |

|

Heat Conducticity

|

w/ m*k |

0.2 |

|

Heat deflection temperature

|

degree |

137.3 |

|

Coefficient of thermal heat expansion

|

Mm/m |

0.063 |

|

Range of temperature

|

degree |

-40-130 |

Polycarbonate Insulated Roofing Sheets Properties

1, High impact strength: the shock strength is 300 times than glass, and 30 times than PMMA

2, With 50um UV layer, Anti UV protection and Anti aging

3, Good light transmission and high heat insulation

4, Fireproof, belong to B1 level fireproof material

Polycarbonate Insulated Roofing Sheets Packing

As with all glazing materials, care should be exercised when handling and transporting polycarbonate sheet in order to prevent scratches and damage to sheet edges. Each sheet is packaged as follows to minimise the risk of these problems:

* The top face is covered with printed ing

* The bottom face use opal film or neutral film

* The edges of the sheets have colored tape on them

* The sheet should be kept in their packaging until immediately prior to installation

Why Choose Polycarbonate Roofing Sheet of OASIS

HAINING OASIS BUILDING MATERIAL CO.,LTD is an professional manufacturer and exporter of polycarbonae sheets. Established on 2011 and Located at Haining city which is between Shanghai airport and Hangzhou Airport.

We have 3 advanced producing line for polycarbonate sheets. Our factory always focus on quality control, scientific management and R&D, so that we can supply the high quality, competitive price and best service for our clients. That is why our products enjoy good markets in worldwide, such as Latin America, Middle east, Africa and south asisa.

On 2015, we established first branch company at Bogota,Colombia, loacated at Calle 68 #22-43.

On 2016, we set another warehouse in Colombia, the address is Carrera 22#14-60,Bogota.

On 2017, we plan to set more warehouse in another city of Colombia, Such as Cali,Baranquilla.

With “quality first, best credit, clients supreme”, welcome warmly you to inquiry and visit us

Polycarbonate Insulated Roofing Sheets Showing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!