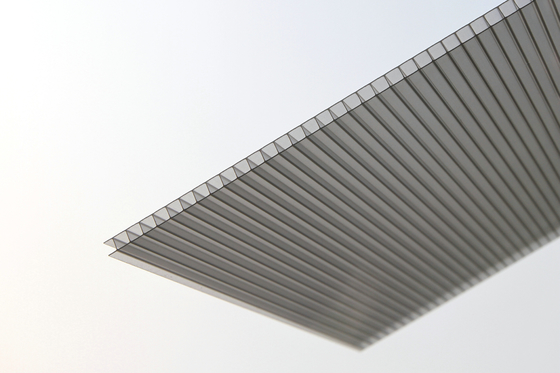

Double Layer Polycarbonate Roofing Sheets For Greenhouse Roofing

What is the Polycarbonate Roofing Sheets ?

Polycarbonate Roofing Sheets is a new kind of engineering plastic with excellent physical and chemical characteristics. Light weight but with high impact resistance, good heat insulation, nice light transmission etc. so it is widely used for construction and decoration.

Polycarbonate Roofing Sheets Specification

(1) Width: 2.1m

(2) Thickness: 4-10mm

(3) Weight: 0.85-1.7kg/sqm

(4) Length: 5.8m, 5.95m, 11.8m

Polycarbonate Roofing Sheets Physical Data

|

soften temperature

|

148℃ |

|

suitable temperature

|

-40 ~120℃ |

|

Anti-fire rating

|

GB8624-1997, B1 level material |

|

elastle stress

|

2400MPa(1mm/rain.ISO 527) |

|

tensile stress

|

63MPa(at yeild 50mm/min.ISO 527) |

|

tensile strain

|

6%(at yeild 50mm/min.ISO 527) |

|

nominal tensile strain

|

>50%(at break 50mm/min.ISO 527) |

Polycarbonate Roofing Sheets Light Transmission For Different Colors

|

Thickness(mm)

Color

|

4 |

5 |

6 |

8 |

10 |

| Light transimission |

|

Clear

|

80% |

78% |

76% |

74% |

72% |

|

Lake Blue

|

56% |

54% |

51% |

49% |

48% |

|

Green

|

55% |

52% |

51% |

48% |

46% |

|

Grass green

|

54% |

52% |

50% |

46% |

44% |

|

Brown

|

34% |

32% |

30% |

26% |

23% |

|

Blue

|

33% |

31% |

28% |

25% |

20% |

|

Opal

|

27% |

25% |

22% |

18% |

15% |

|

Advertising white

|

16% |

14% |

12% |

9% |

8% |

Polycarbonate Roofing Sheet Installation Instruction

1. Expose only the face that has the UV protection if the sheets include 1-side UV co-extrusion layer. Double-side UV can expose either side face to sunlight.

2. Store sheets on flat surfaces. Use an opaque cover, tightly secured, to protect from wind, rain and sun. Storage is always preferable indoors.

3. Sheets should be install with the rib channels are sloping downwards. That orientation will reduce accumulation of dirt inside the sheet and ease gravity drainage of condensation moisture.

4. Allow enough or lengthwise and widthwise for expansion of sheets.

5. Improved performance can be obtained by replacing the washers with special plastic screw buttons, fitted with a suitable rubber gasket, with or without a closing cap. They fit the thickness of each type of sheet (6, 8, 10, 16mm, and possibly 25 mm), differing by sleeve length.

6. Never walk on the sheets directly. Always use wooden boards mounted in the same direction of the structural supports.

7. Self-cleaning by rain is usually sufficient. Using diluted mild household detergents. Make sure the detergent contains no abrasives or solvents. Pre-wash with warm water, then wash the stained area with a soft sponge or brush, preferably with hot water, until the stain disappears. Rinse with water and dry with a soft cloth.

8. Saw blades designed especially for plastic yield best results. A circular saw (fixed or portable, with small teeth suited for hardwood), rotating at high speed, band saw or a jigsaw (best for short, complex cuts) can all be used, taking care to advance the blade slowly. A hand and hacksaw may also be used for local cutting.

What Can Polycarbonate Sheet Be Used For?

Polycarbonate sheets can be used in a wide range of applications including airports, stadiums, and public spaces. Polycarbonate sheets are also extremely suitable for private use, including in greenhouse roofing or glazing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!