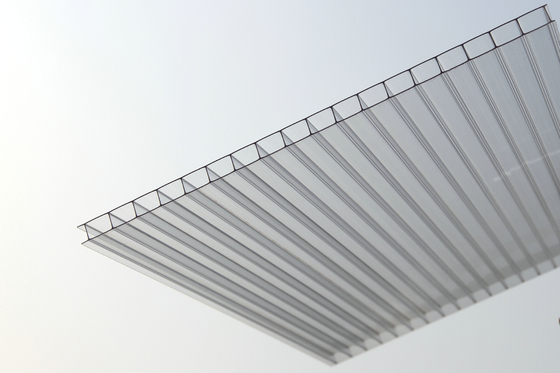

Heatproof Polycarbonate Roofing Sheets For Workshop Storehouse Skylights

Polycarbonate Roofing Sheets Introduction

Polycarbonate Roofing Sheets is made by polycarbonate resin. On the basis of common pc solid sheet's technique and improvements of molds and production, the optical properties are changed as the surface structure of the product varies. Single side of pc corrugated sheet contains UV protective layer, therefore, its mechanical properties, fire retardation, applicable temperature and chemical properties are consistent with common solid sheet. By changing the physical shape of the surface, when light gets through the embossed sheet, it produces light scattering to get a vague hazy effect. Currently, pc corrugated sheet is very ideal architecture material.

Polycarbonate Roofing Sheet Main Application

1, Building skylights; such as gymnasium, workshop, storehouse etc.

2, Agriculture greenhouse

3, Natatorium coverings

4, Walkway; Carport

5, Indoor partition; Folding screen

6, Furniture; Bathroom

Polycarbonate Roofing Sheet Specification

1. Standard size: Width 2100mm×Length 11800mm; size also could be ordered

2. Thickness: 6mm

3. Min. Bend Radius: 1050mm

4. K value: 3.6W/㎡K

Light Transmission of Polycarbonate Roofing Sheet

|

Thickness(mm)

Color

|

4 |

5 |

6 |

8 |

10 |

| Light transimission |

|

Clear

|

80% |

78% |

76% |

74% |

72% |

|

Lake Blue

|

56% |

54% |

51% |

49% |

48% |

|

Green

|

55% |

52% |

51% |

48% |

46% |

|

Grass green

|

54% |

52% |

50% |

46% |

44% |

|

Brown

|

34% |

32% |

30% |

26% |

23% |

|

Blue

|

33% |

31% |

28% |

25% |

20% |

|

Opal

|

27% |

25% |

22% |

18% |

15% |

|

Advertising white

|

16% |

14% |

12% |

9% |

8% |

Polycarbonate Roofing Sheet Packing

As with all glazing materials, care should be exercised when handling and transporting polycarbonate sheet in order to prevent scratches and damage to sheet edges. Each sheet is packaged as follows to minimise the risk of these problems:

* The top face is covered with printed ing

* The bottom face use opal film or neutral film

* The edges of the sheets have colored tape on them

* The sheet should be kept in their packaging until immediately prior to installation

Why Choose Polycarbonate Roofing Sheet of OASIS

HAINING OASIS BUILDING MATERIAL CO.,LTD is an professional manufacturer and exporter of polycarbonae sheets. Established on 2011 and Located at Haining city which is between Shanghai airport and Hangzhou Airport.

We have 3 advanced producing line for polycarbonate sheets. Our factory always focus on quality control, scientific management and R&D, so that we can supply the high quality, competitive price and best service for our clients. That is why our products enjoy good markets in worldwide, such as Latin America, Middle east, Africa and south asisa.

On 2015, we established first branch company at Bogota,Colombia, loacated at Calle 68 #22-43.

On 2016, we set another warehouse in Colombia, the address is Carrera 22#14-60,Bogota.

On 2017, we plan to set more warehouse in another city of Colombia, Such as Cali,Baranquilla.

With “quality first, best credit, clients supreme”, welcome warmly you to inquiry and visit us

Polycarbonate Roofing Sheet Showing

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!