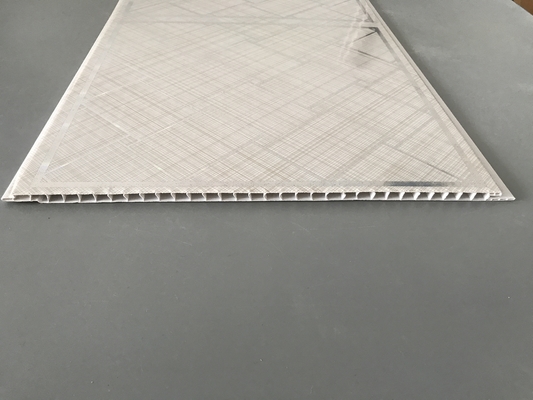

Waterproof Ceiling PVC Panels Plastic Ceiling Sheets For Wet / Dry Areas

Ceiling PVC Panels Application:

Ceiling PVC panels is a new type of decoration materials in recent years, we can use the ceiling pvc panels in any place of interior decoration, such as the hotel, bedroom, bathroom, kitchen, it is matched well with any decoration material. you can decorate the wall and ceiling quickly without paint. Especialy it is an idea material for ceiling and bathroom, where is moisture and oil.

With our ceiling pvc panels you’re able to clad your walls with a strong, durable and waterproof covering that’s easy to install and maintain as well as being mould resistant.

If you’re looking to cover your bathroom walls, ceiling or shower recess area with a waterproof, mould resistant material that looks great and is easier to maintain than tiling then our ceiling pvc panels could be exactly what you’re after.

Ceiling PVC Panels Quick details

| Product |

Waterproof Ceiling PVC Panels Plastic Ceiling Sheets For Wet / Dry Areas |

| Size |

200mm×7mm |

| Length |

5.8 m for 20' GP container, 5.95 m for 40' HQ, or be requested |

| Package |

Packed with PE-film, 10 sheets per bag |

| Surface treatment |

Printing |

| Weight |

2.30kg/m2 |

| Payment |

Accept T/T or 100% L/C at sight |

| Lead time |

Usually 15-20 days for 40' HQ |

Main features

- Suitable for wet and dry areas

- Easy and quick to install

- Easy to clean and hygienic

- A cost-effective alternative to tiling

- Non-porous and mould free

- Virtually maintenance free

- Provides excellent insulation and sound proofing

- Suitable for domestic installations

- Beautiful apperance with many color choice

1) Ceiling PVC panels can be fixed directly to the wall if the surface is relatively even and if the wall is dry, using shower panel adhesive, or fix on to a frame of wooden batons.

2) When fitting ceiling PVC panels, always fix to a frame of wooden batons.

3) When fixing ceiling PVC panels to wooden batons, the panels can be fixed through the extending backplate fixing tongue using staples with a staple gun, by hammer with panel pins / nails, with screws, or with panel adhesive.

4) To make a wooden frame, strap the wall with wooden battens placed approximately every 30-40cm according to the direction of assembly. If panels are assembled vertically, strap in the opposite direction horizontally, and vice-versa. If panels are assembled diagonally, the batons can be installed vertically, horizontally, or at right angles to the panels.

5) Start with the preferred end cap U, internal, external, or scotia. Insert the tongue side of the panel into the moulding.

6) Glue the panel, or panel-pin (nail), staple or screw the first panel through the backplate fixing tongue opposite the starting side.

7) Insert the tongue of the next panel into the groove and continue the installation of the panels in the same manner.

8) Use appropriate PVC profiles to finish all corners and ends.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!