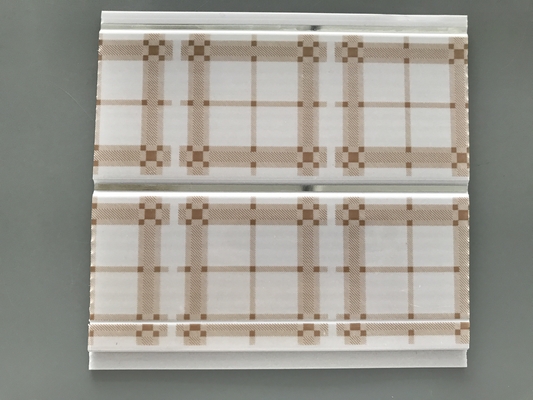

Groove Width 200 MM Ceiling PVC Panels With Common Printing Surface

OASIS also offers our clients with PVC Ceiling & Wall paneling in order to enhance the beauty of the homes, offices and public places. These are available in variety of colors, shades and patterns and are easy to maintain and clean. These products are flexible and can be easily folded to relocate it from place to another. Our range of PVC ceiling and wall paneling can be customized as per the clients specifications and configuration The PVC ceiling & Wall Panellings are non-porous and non-absorbent thus helping in safe fitting of flush , lighting, access-hatches, air- vents and sprinklers.

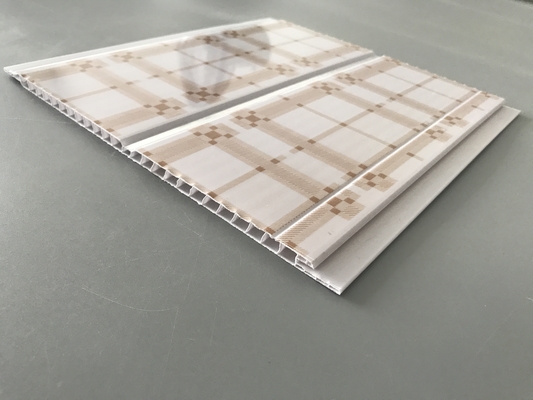

PVC Ceiling Panel Measurement:

| MATERIA |

PVC resin, calcium carbonate, some other ingredients |

|

SPECIFICATION

|

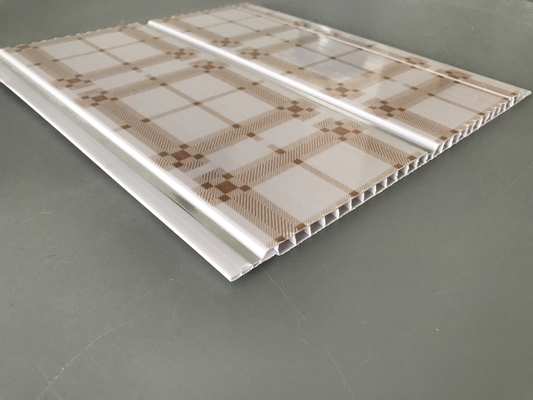

Width×Thickness (MM) |

PVC content |

Length (MM) |

| 200×6 |

40%

45%

50%

55%

60%

|

5800mm for 20’GP

5950mm for 40’HQ

|

| Surface process |

Common printing |

| PACKAGE |

PE film(bundle) |

PVC Ceiling Panel Main Features:

|

1.

|

Durable and hygienic surface

|

|

2.

|

Water and termite proof

|

|

3.

|

Fire retardant

|

|

4.

|

Easy to install

|

PVC Ceiling Panel Detailed Features:

1. Water Proof

Our products are waterproof and do not expand, contract or wharp when they come in touch with water.

2. Termite Proof

Our products are Termite proof and no termites or other insects can harm the product unlike other traditional material, which disintegrate when termite or insects attack it.

3. Fire Retardant

Our products burns when subjected to flame, but does not burn by itself: The product extinguishes immediately when the external flame source is removed. It has got a "B1" class fire rating.

4. Economical

The prices of our products are very economical even when compared to the other alternates available in the market and apart from this it also delivers many other advantages.

PVC Ceiling Panel Installation:

1. Clean the surface of ceiling.

2. Nail wooden or steel battens(20mm - 30mm thick) into the wall and ceiling, with all the corners firstly, then on the plane with the distance of 400mm away between every wooden batten.

3. Screw PVC profiles(cornices) on all the corners, then insert the panel into the corner profiles, then the folling panel into the first panel.

4. Screw PVC second panel's notch side into the wooden or steel battens, then insert the third panel, then the fourth, and nail the fourth's notch side, then fifth and sixth, then...

5. Attention for the distance and notch side panel: for the ways above is based on 250mm or 300mm wide panels, and wooden or steel battens between distance is 400mm, so every 2 panel, screw the second notch. Surely you could change the ways as per your situation presently, by way of changing the distance of the panels and the wooden or stell battens.

PVC Ceiling Panel Application:

PVC panel is widely used for Office, Hotel, Household, Hospital, Restaurant, Shopping Mall, Kitchen, Bathroom, Garage, etc. Those are all for indoor decoration, especially for ceiling and wall part.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!